When it comes to securing loads for transport, pallet wrapping machines are essential. These machines streamline the wrapping process, ensuring your products stay safe during shipping. But with options ranging from manual to fully automatic machines, how do you decide which is the right fit for your business? Let’s break it down!

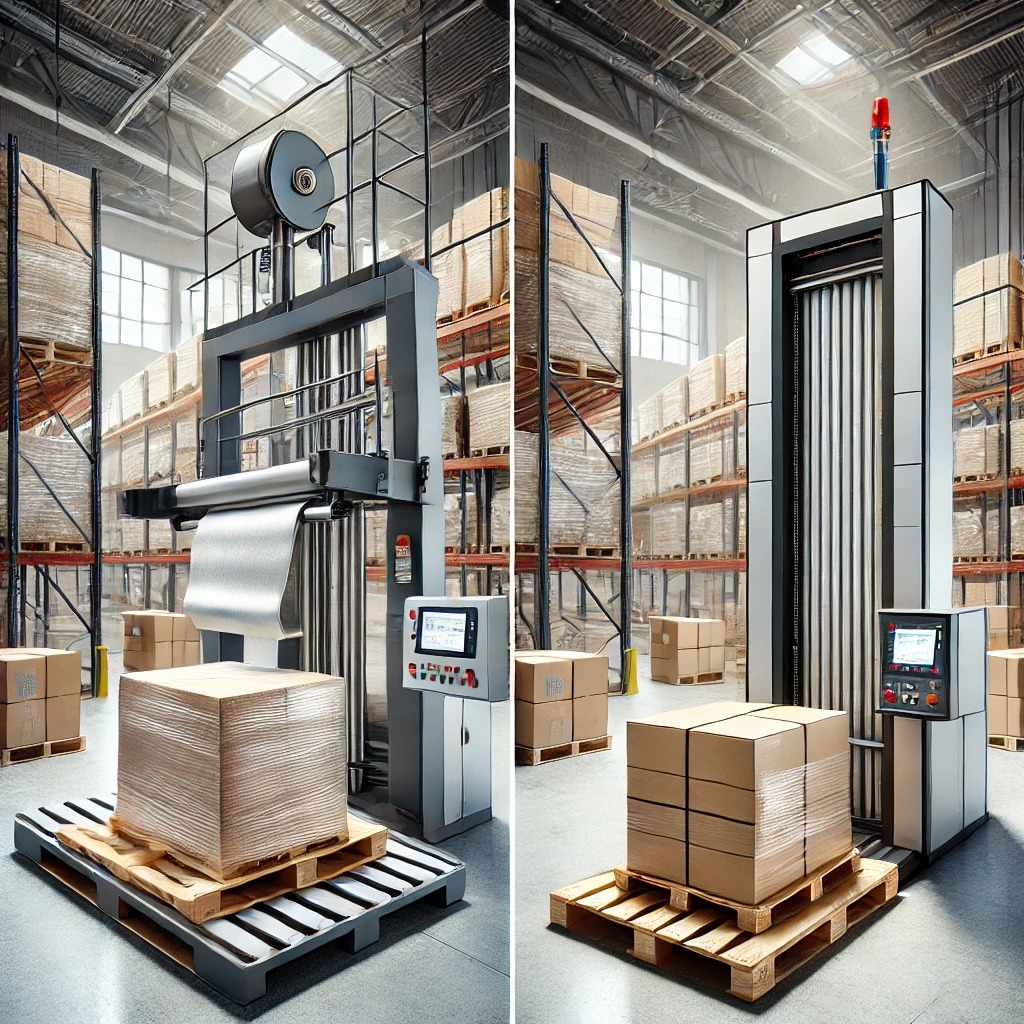

Manual Pallet Wrapping Machines

Manual pallet wrapping machines are a simple and cost-effective solution for businesses with lower output requirements. These machines require some human intervention, such as attaching the stretch film and controlling the wrapping cycle manually.

Benefits:

1. Affordable Investment: Manual machines are budget-friendly, making them an excellent choice for small businesses or those just starting.

2. Compact Design: They take up minimal space, ideal for businesses with limited warehouse areas.

3. Control and Precision: Operators have direct control over the wrapping process, which can be advantageous for wrapping delicate or irregularly shaped loads.

Drawbacks:

Labour Intensive: Since these machines require manual operation, they may not be suitable for businesses with high wrapping demands.

Consistency Challenges: Wrapping quality can vary depending on the operator’s skill and effort.

Automatic Pallet Wrapping Machines

Automatic pallet wrapping machines are designed for efficiency and high output. They handle the entire wrapping process with minimal human intervention, from attaching the film to completing the wrap.

Benefits:

1. Time Efficiency: These machines can wrap multiple pallets quickly, boosting productivity.

2. Consistency: Automatic machines deliver uniform wrapping every time, ensuring secure loads.

3. Labour Savings: With reduced reliance on manual labor, businesses can allocate workers to other critical tasks.

4. Advanced Features: Many automatic machines come with programmable settings, making them adaptable to various load types.

Drawbacks:

Higher Initial Cost: Automatic machines require a larger upfront investment.

Space Requirements: They often need more room, which might not suit small warehouses.

Which One Should You Choose?

The right choice depends on your business’s needs, budget, and operational scale. Consider the following factors:

Volume of Work: If you wrap only a few pallets a day, a manual machine is a practical choice. For higher volumes, automatic machines are more efficient.

Budget: Smaller budgets favor manual machines, while businesses with long-term growth in mind may benefit from the efficiency of an automatic model.

Workforce: Evaluate how much labor you can allocate to pallet wrapping. Automatic machines can significantly reduce manual effort.

Conclusion

Both manual and automatic pallet-wrapping machines have their place in the world of logistics and packaging. Understanding your specific requirements will help you make an informed decision. Whether you prioritize cost-effectiveness or efficiency, there’s a solution that fits your needs.

Explore your options and choose wisely—because secure shipments mean happy customers!

Write a comment ...